Imagine you’re storing thousands of tons of grain. Everything seems fine until it’s not. Pests can infiltrate silos quietly, multiply fast, and cause severe damage before anyone notices. Traditionally, grain pest detection relied on visual inspections or traps. But those methods are slow and reactive. Now, something different is entering the scene: electronic noses.

These high-tech devices, inspired by the human sense of smell, are beginning to change how the grain industry handles pests. By detecting infestation signs early, they help prevent massive losses and contamination. And while they sound futuristic, they’re already being tested in real-world silos and storage units.

For those dealing with common summer pests or rodent threats in homes and businesses, these early detection innovations may eventually stretch beyond agriculture. In regions where pest activity is especially high, such as those covered by pest control services in Acworth, the need for faster and more accurate detection is becoming increasingly clear.

What Are Electronic Noses?

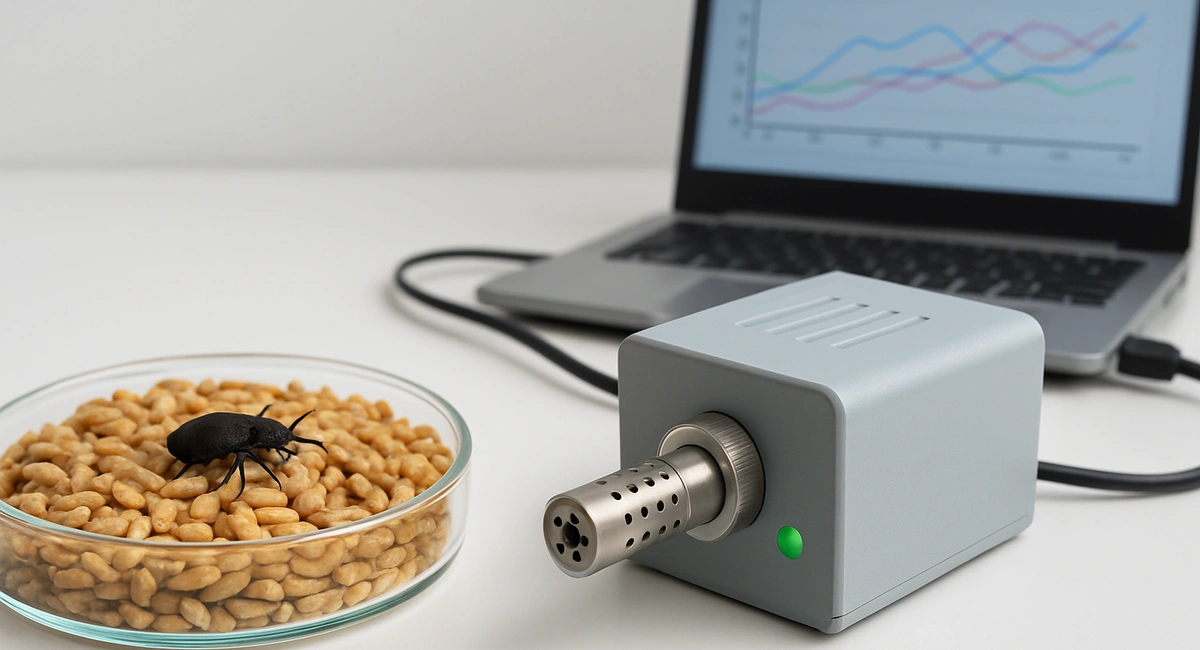

Electronic noses, or “e-noses,” are sensor-based devices designed to mimic human olfaction. They don’t sniff like we do, but they analyze the chemical makeup of odors. When pests like weevils, beetles, or moths invade grain, they release specific volatile organic compounds (VOCs). An e-nose picks up on these chemical traces.

The device uses an array of gas sensors, machine learning algorithms, and data analysis tools to detect and classify smells. In a way, it builds a scent memory and uses that to identify new threats.

Why Traditional Methods Fall Short

Conventional grain monitoring methods are useful, but they often work too late.

- Manual inspection can miss tiny infestations

- Traps take time to show results

- Temperature and moisture monitoring don’t always link directly to pest presence

- Lab testing requires time and sample collection, slowing down response

By the time signs become visible, pests may already be damaging the grain or laying eggs. That’s where e-noses provide a major edge because they detect problems before there are visible signs.

How Electronic Noses Work in Grain Storage

When installed in grain silos or storage bins, e-noses continuously sample the air. They analyze airborne chemicals and compare them to known profiles of pest-related VOCs. If something matches, the system alerts operators.

Here’s a simplified breakdown of what happens:

- Air is pulled from the grain bin

- Sensors capture VOCs and send signals to the processor

- Machine learning software compares it with known pest signatures

- An alert is issued if a match is found

This happens in real-time, often integrated with mobile apps or dashboard systems.

Key Benefits for the Grain Industry

The use of e-noses in agriculture offers several advantages that go beyond early detection:

- Reduce grain waste by catching pests before damage spreads

- Cut down on pesticide use by targeting infestations specifically

- Improve food safety with faster interventions

- Enable predictive pest control aligned with seasonal pest patterns

Over time, these systems can be fine-tuned to detect multiple pest types, storage mold, and even chemical residues. This versatility makes them valuable for food processors and exporters alike.

Growing Need for Smarter Detection Tools

The global food supply is under pressure from climate changes, transport delays, and rising pest resistance. As temperatures climb, pest activity increases. In regions like Georgia and Florida, where pest populations spike during warmer months, prevention becomes even more important.

E-nose technology is likely to play a role in broader pest control efforts, alongside traditional tactics. In commercial settings, combining these tools with regular inspections like those used in warehouse pest control practices can improve outcomes.

Real-World Applications and Early Success

Field trials of electronic noses have been conducted in Australia, India, and the U.S. Some systems have successfully identified specific infestations like the red flour beetle, a common threat in stored wheat. Researchers are now training the devices to differentiate between pest stages such as larvae and adult beetles, which is key in deciding intervention strategies.

These tools are also being tested in food processing units, where contamination control is tight. Just as a pest-free restaurant environment is essential for customer trust, grain processors need assurance that their products are safe and pest-free.

Challenges Still Ahead

While the promise is strong, electronic noses face a few hurdles.

- Calibration takes time, especially in mixed grain environments

- Cost is still high, though dropping with wider adoption

- Maintenance requires trained staff

- False positives are possible if the environment changes suddenly

Even with these challenges, the direction is clear. As technology advances, accuracy improves, and costs fall, e-noses are becoming more accessible for both large-scale and smaller operations.

How This Tech May Evolve

Future versions of e-noses may become portable, cheaper, and more connected. With integration into IoT networks, these devices can offer predictive insights across multiple sites. Imagine an entire supply chain monitored by scent-based devices, reporting issues before a shipment even leaves the warehouse.

They may also work alongside drones, robotic grain samplers, and AI-driven analytics, making pest detection part of a larger smart farming ecosystem.

For businesses dealing with pest risks year-round, like offices or hospitality locations, adopting preventive measures is key. Take a look at the benefits of office pest management to understand how proactive steps can reduce risks across industries.

FAQs: What People Want to Know

Can electronic noses detect all types of grain pests?

Not all, but many. As their scent libraries grow, they’re getting better at identifying different pests and their life stages.

Are e-noses used outside agriculture?

Yes. They’re also used in food safety, environmental monitoring, and even disease detection in humans.

How accurate are they?

Accuracy depends on the model and training. Some have shown over 90 percent accuracy in early pest detection trials.

Is it worth using for small farms?

At current costs, they are more suitable for larger operations. However, as technology matures, affordability for smaller farms is improving.

How are e-noses different from gas detectors?

Gas detectors usually look for specific gases. E-noses analyze a mix of compounds and identify patterns related to specific odors like those from pests.

Final Thoughts

Electronic noses are quietly changing the rules in pest detection. For industries where early pest control can mean the difference between profit and loss, this tool offers new hope. Grain operators, food processors, and even commercial businesses are looking at how this innovation fits into their broader pest control plans.

As adoption grows, it will become a part of smarter, data-driven approaches to pest management. For now, combining traditional control with smart tech along with strategies like early signs of termite damage monitoring or seasonal pest calendars can create stronger protection for both food and facilities.

Pests may be sneaky, but technology is learning to sniff them out before they cause harm. The nose knows, especially when it’s electronic.